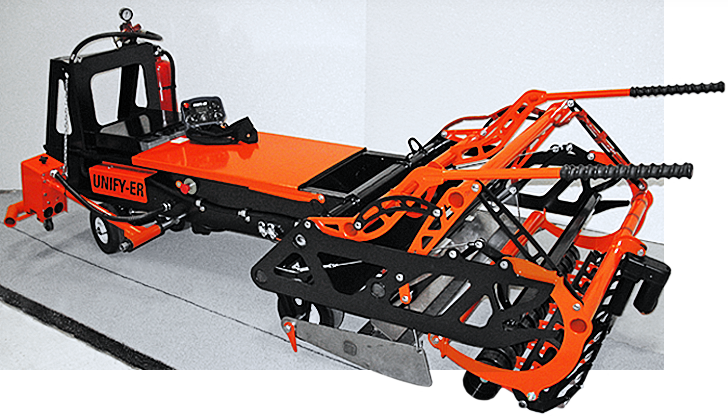

UNIFY-ER

AUTOMATED INSTALLATION SYSTEM FOR MODIFIED BITUMEN MEMBRANE

ROOFS • PARKINGS • BRIDGES

Specifications

Specifications

- Electrical operation without extension cord

- Low noise system with remote control

- Robust and lightweight machine for easy transportation

- Ecological and safe operation

- Easy loading system of the membrane rolls

- Automatic laser guidance system

- Lighter than other existing equipment on the market

- Lifting by 4 operators only

- Reduced size to fit in a Pick-up truck

- Perfectly balanced for lifting up

- Tank directly installed on the machine – no need to unwind hoses

- No venting required for LP gas

- Compatibility with all major membranes

manufacturers on the market

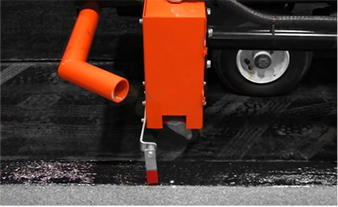

- Quality control of work performed

with the machine

COMPARATIVE TABLE

| Job site example for 2 800 rolls; | Torch welding | UNIFY-ER |

|---|---|---|

| NUMBER OF EMPLOYEES | 5 | 3 |

| AVERAGE ROLLS / HOUR À L'HEURE |

12 | 18 |

| MEN HOURS TO COMPLETE | 233 | 155 |

| CREW HOURS TO COMPLETE | 1 165 | 465 |

| AVERAGE COST / HOUR | 50$* | 50$* |

| TOTAL LABOR COST | 58 250$* | 23 250$* |

*Comparisons are based on estimates and vary depending on local labour rates.

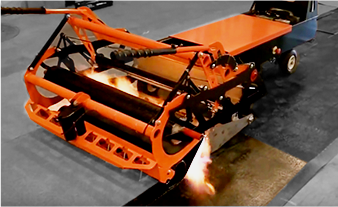

• Automatic electric ignition with ajustable solenoid valve

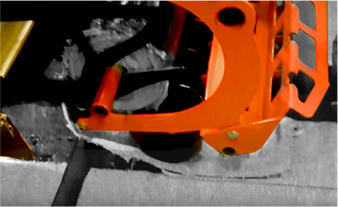

• Easy and secured loading system of the membrane rolls

• High working speed

• Remote control for better quality control

• No extension cord or propane cable

• Automatic laser guide for perfect installation